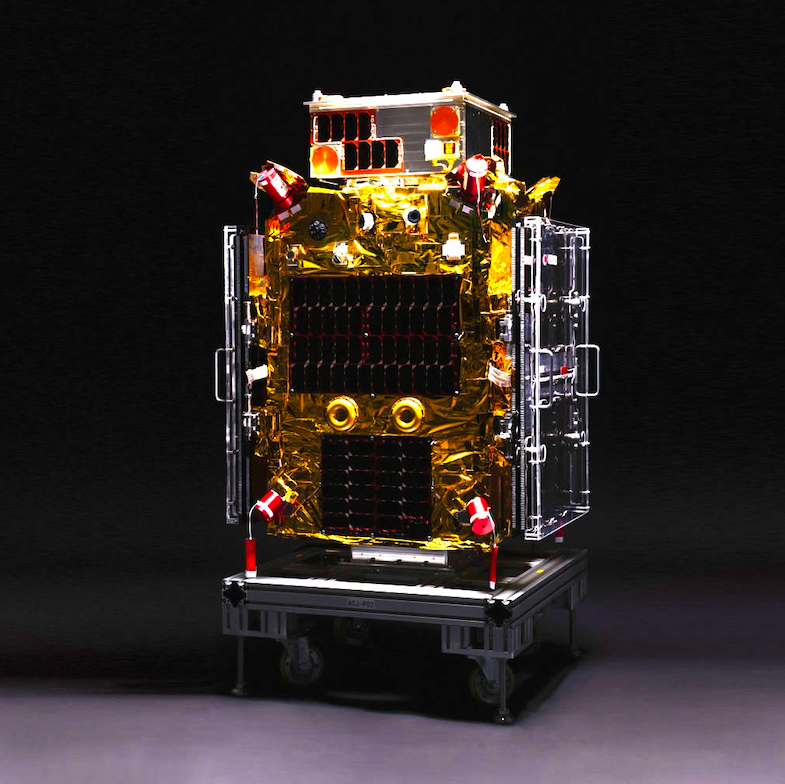

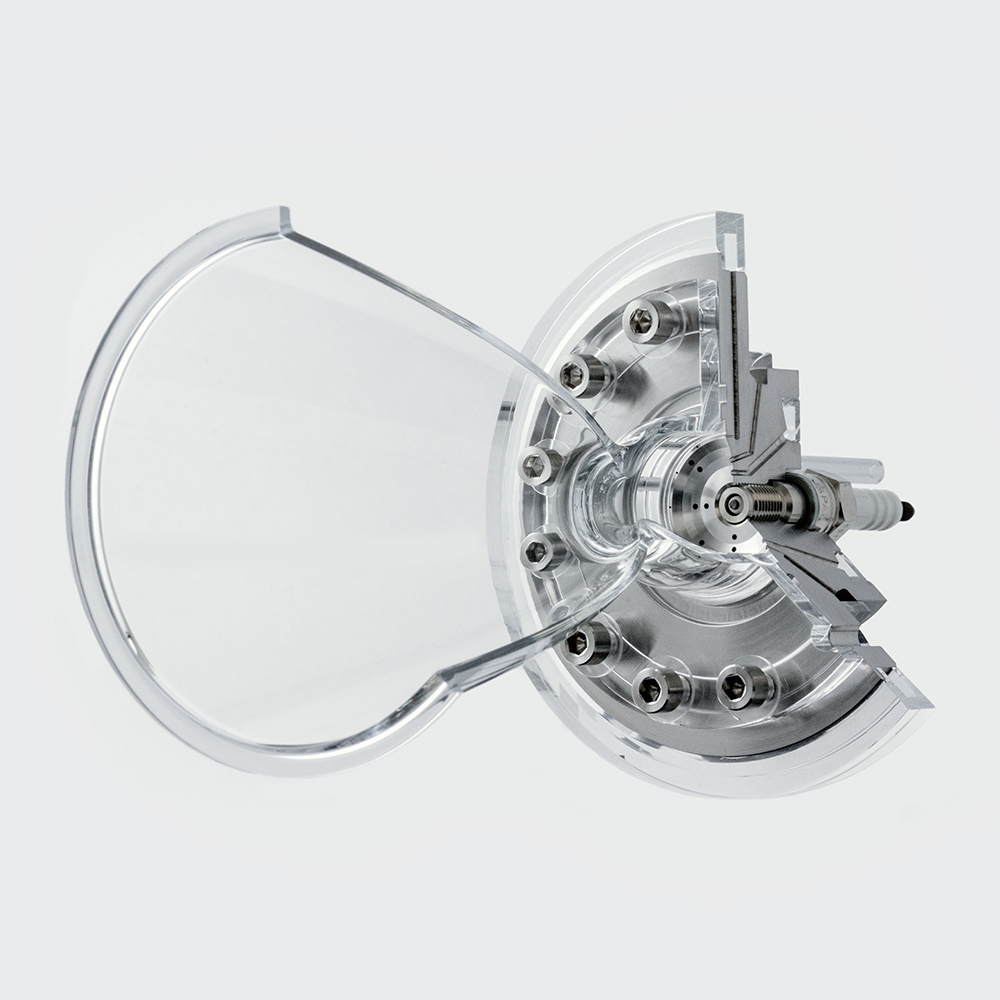

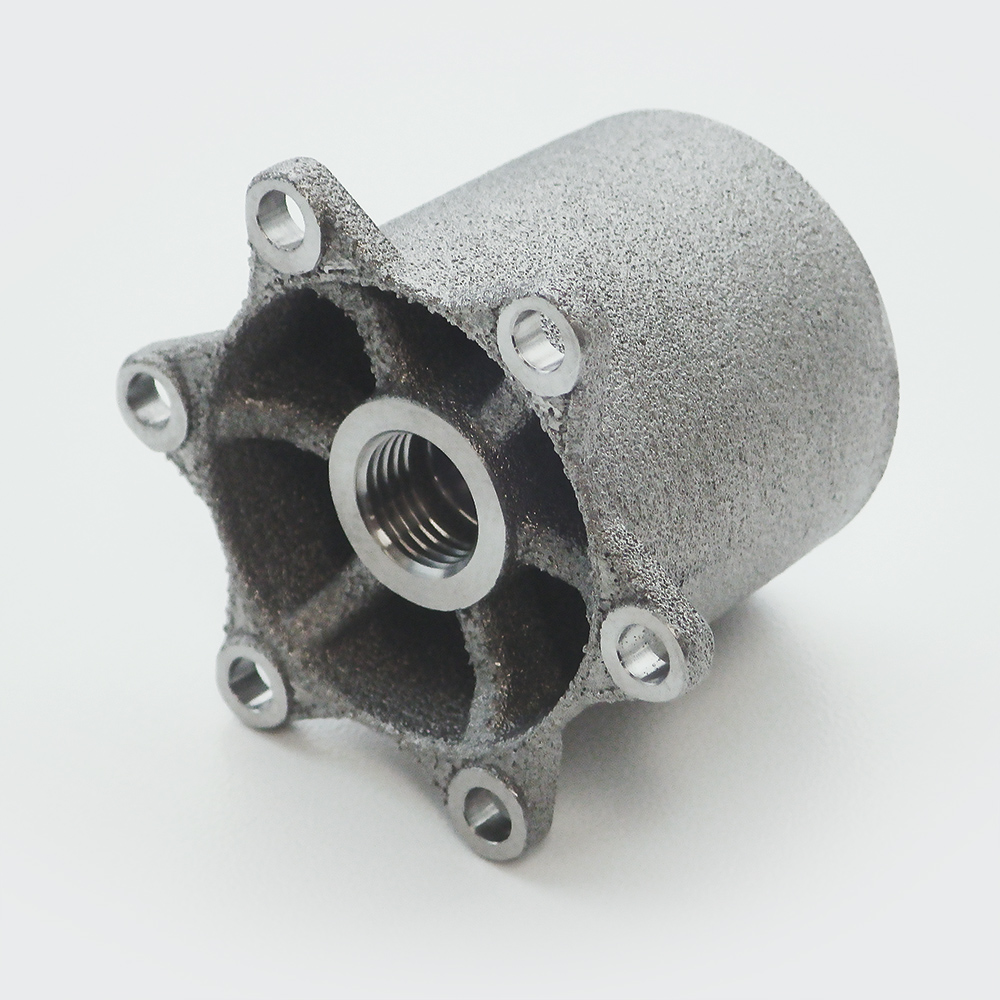

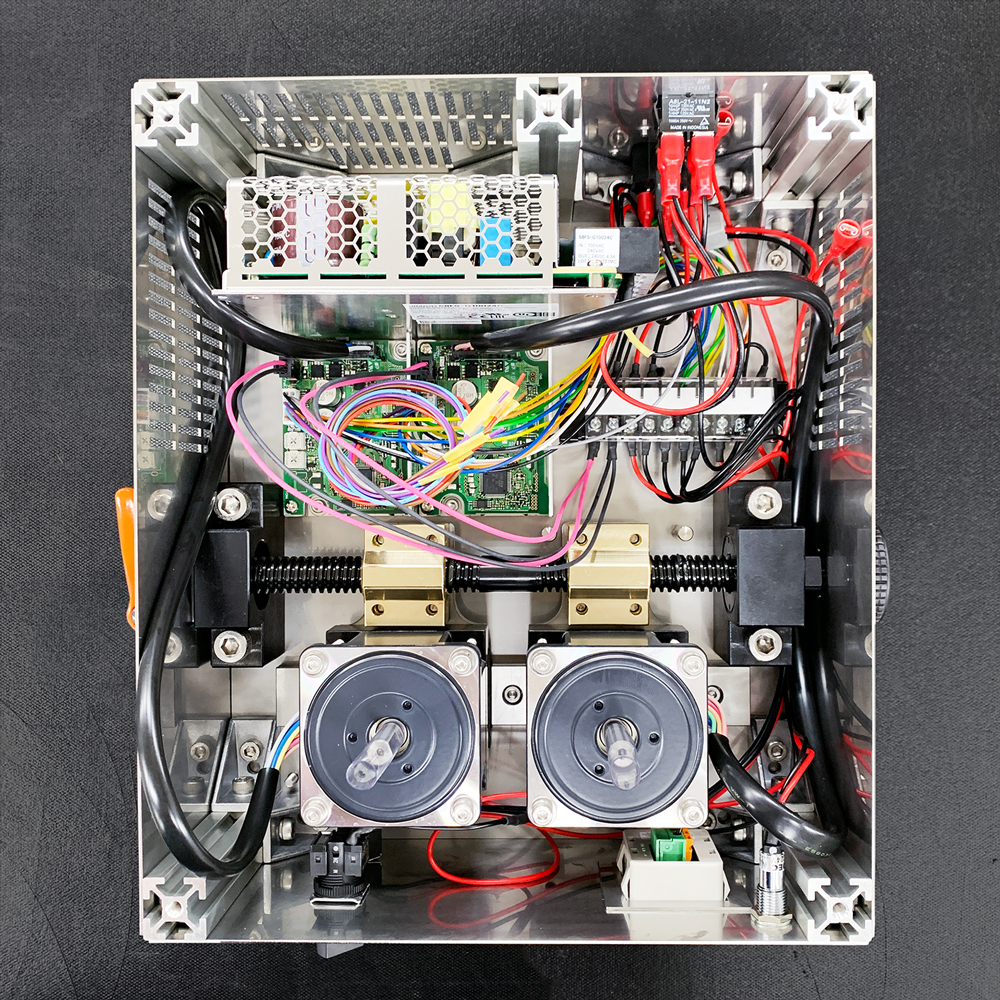

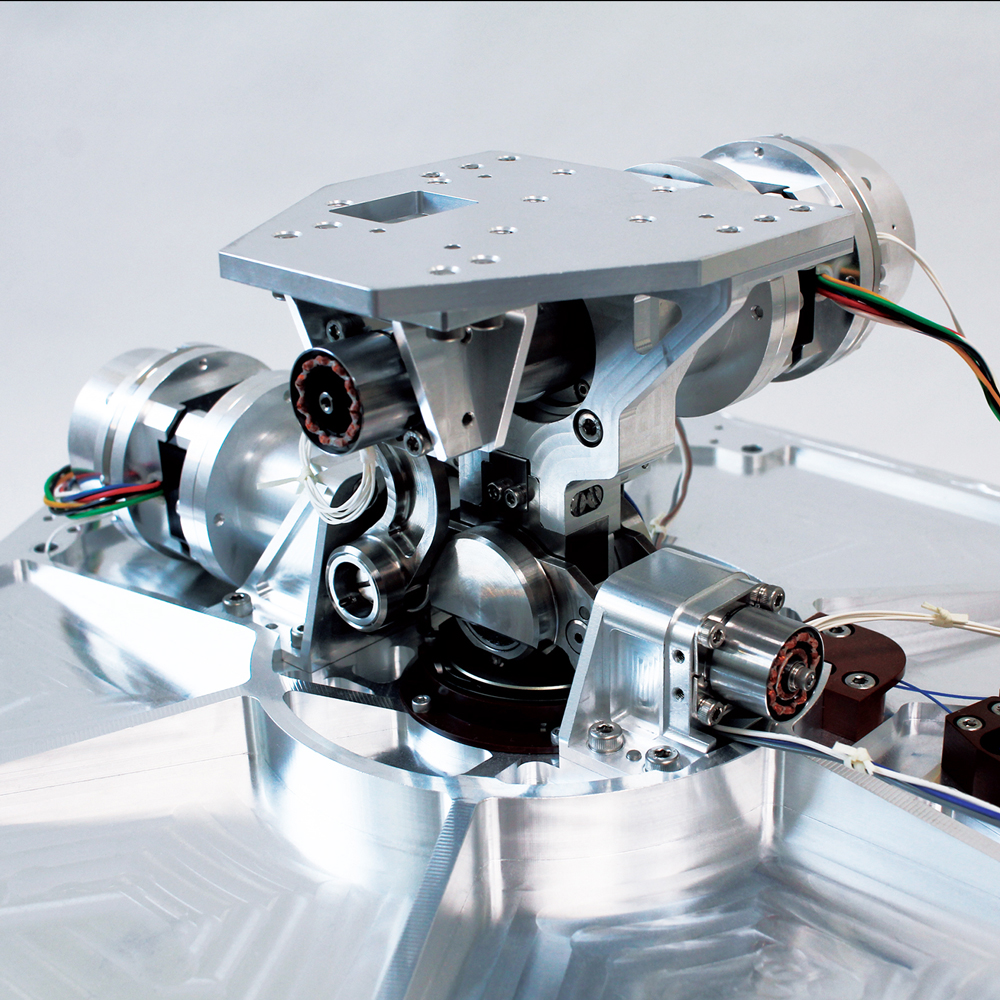

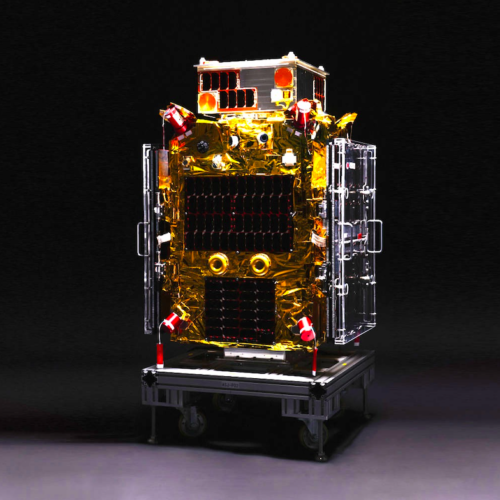

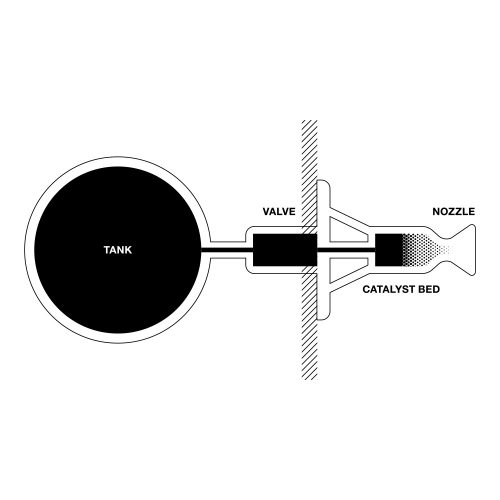

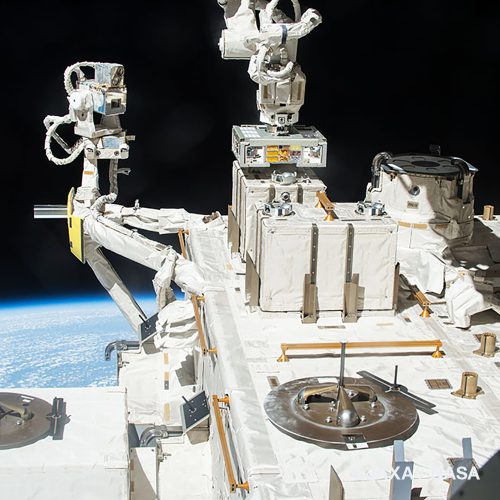

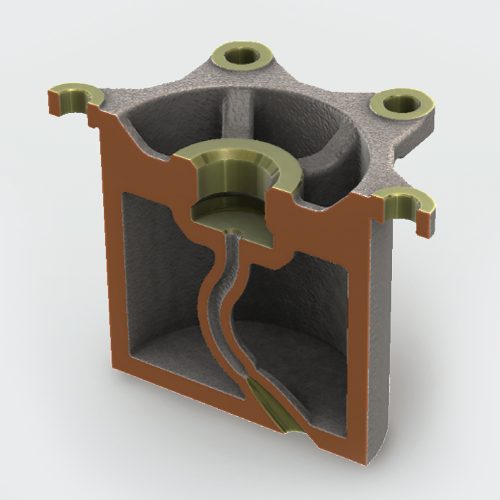

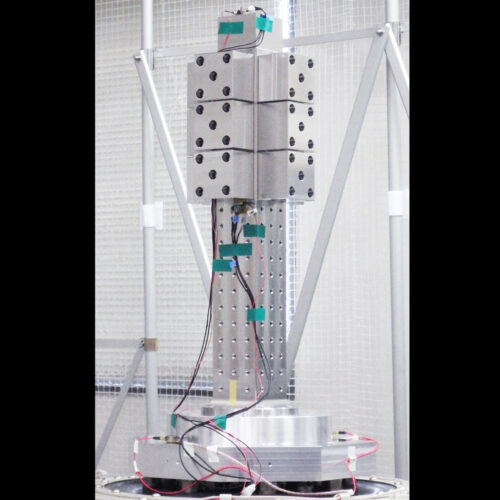

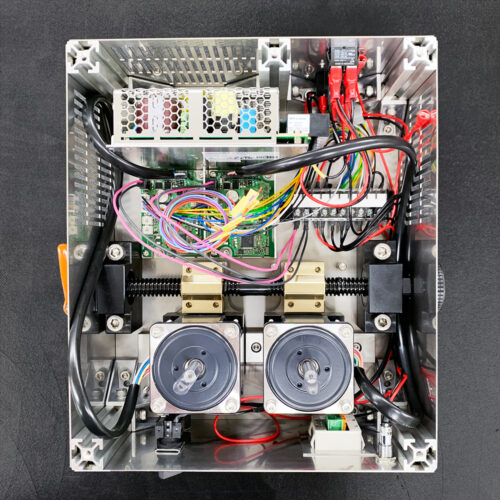

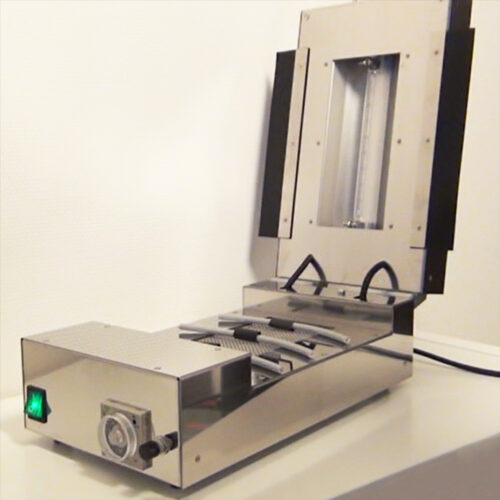

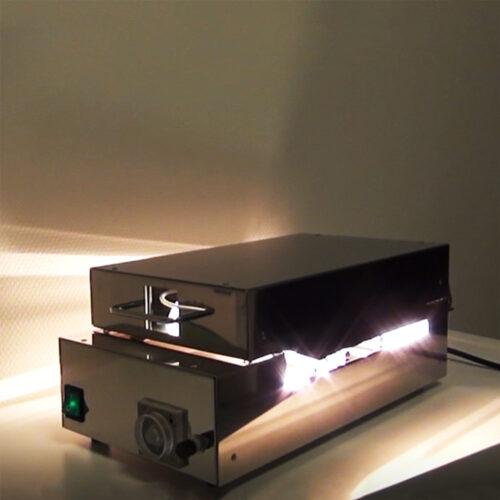

ELSA-d Capture mechanism

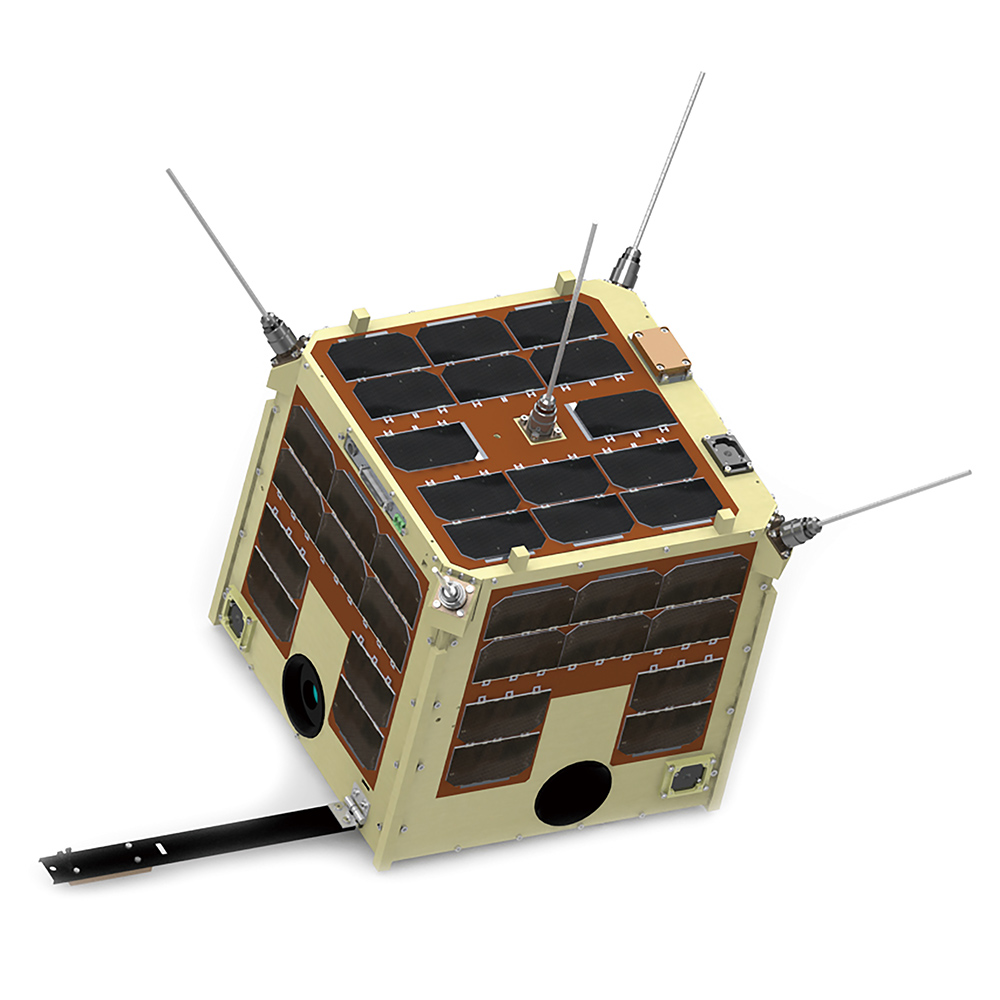

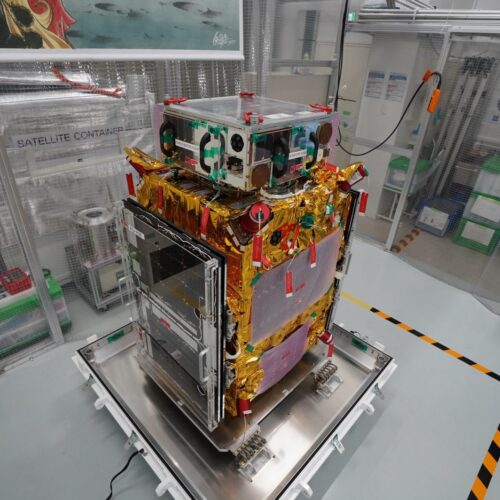

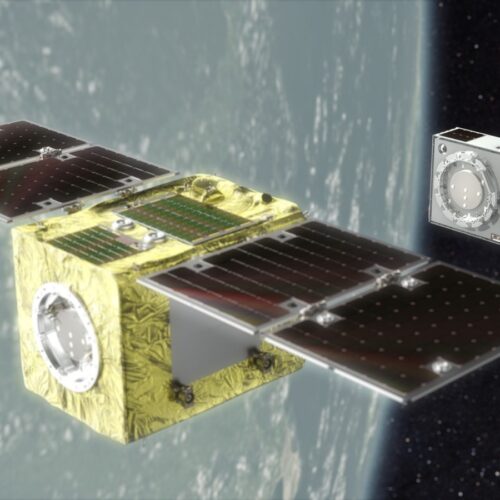

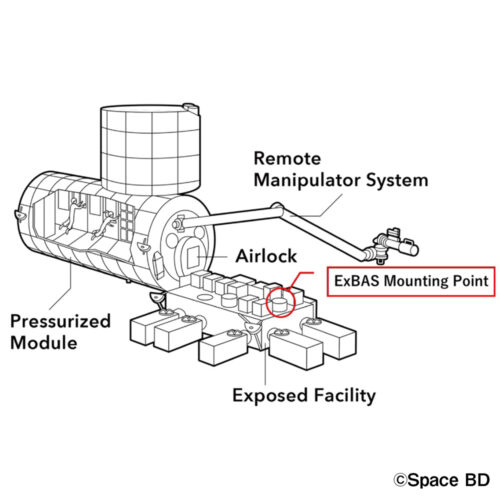

ELSA-d is the world's first space debris removal demonstration satellite that demonstrates a series of core technologies related to space debris removal.

It consists of a "capture machine" and a "simulated debris".

Launched from the Kazakhstan Standby Konur Space Station on March 23, 2021, and successfully demonstrated the capture of simulated debris in orbit on August 26.

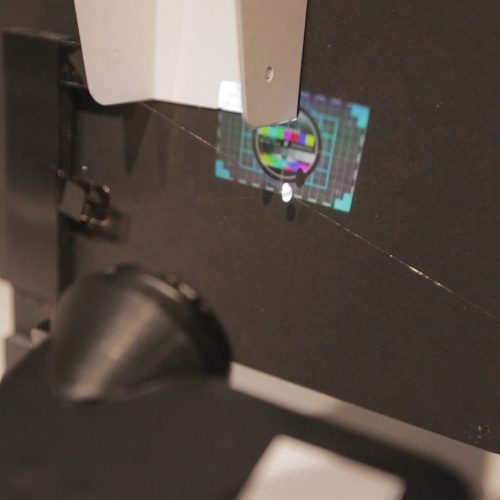

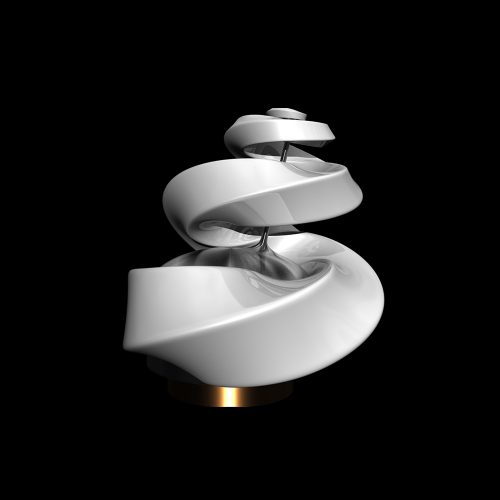

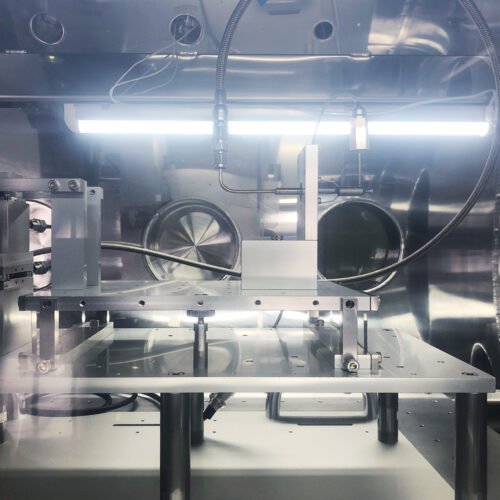

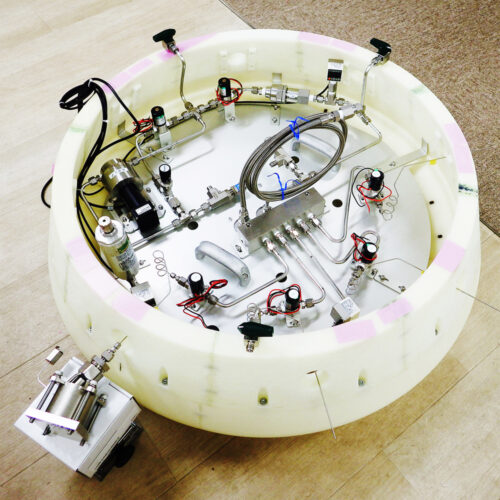

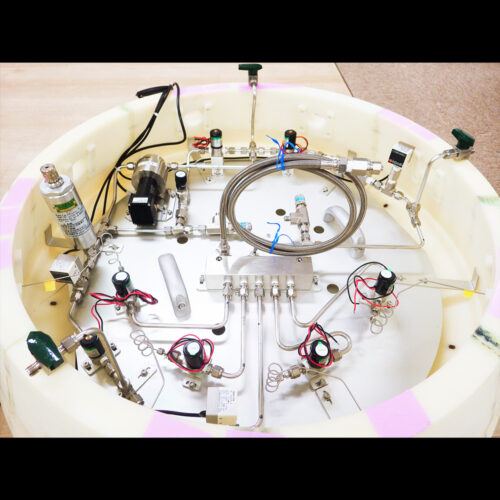

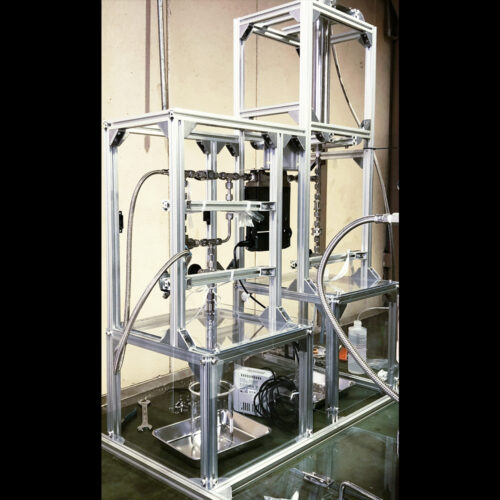

YUKI Precision designed and manufactured the capture mechanism.

| Category | Contract |

|---|---|

| Clients | ASTROSCALE PTE. LTD. |

| Duration | 2017 – 2020 |

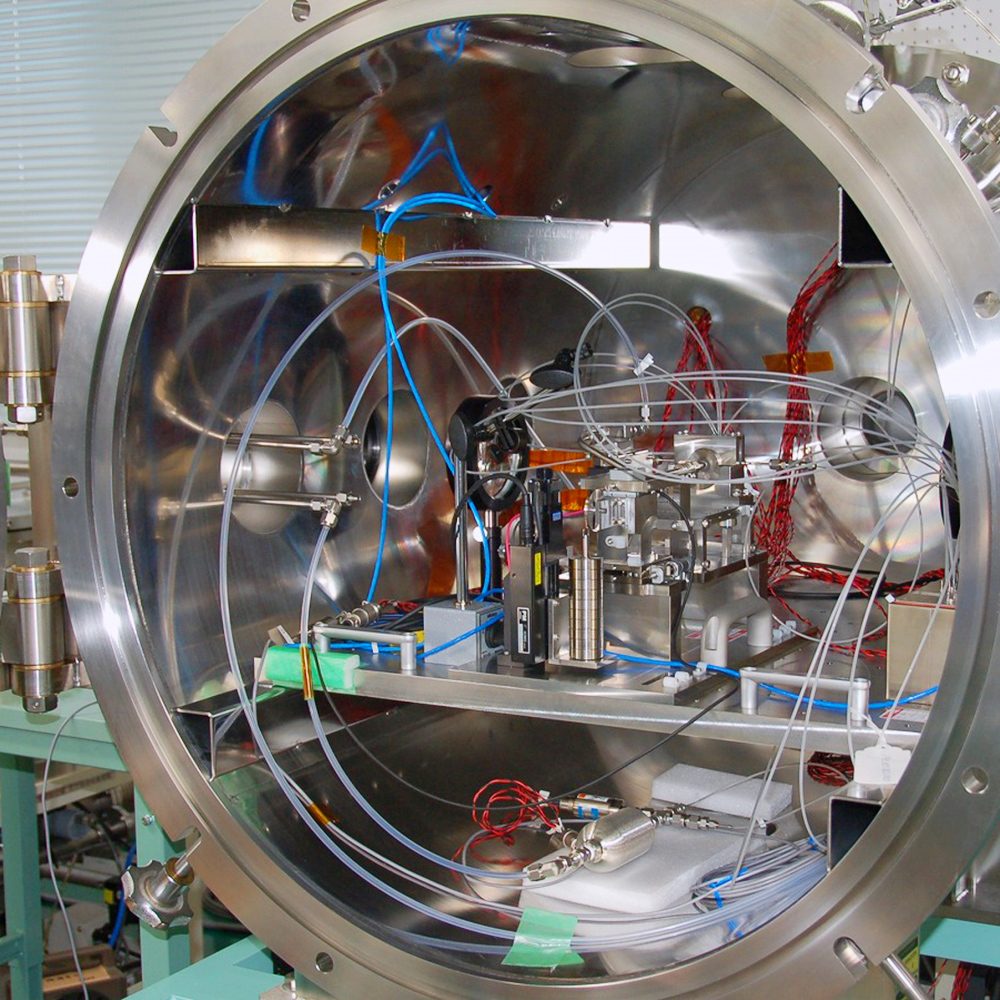

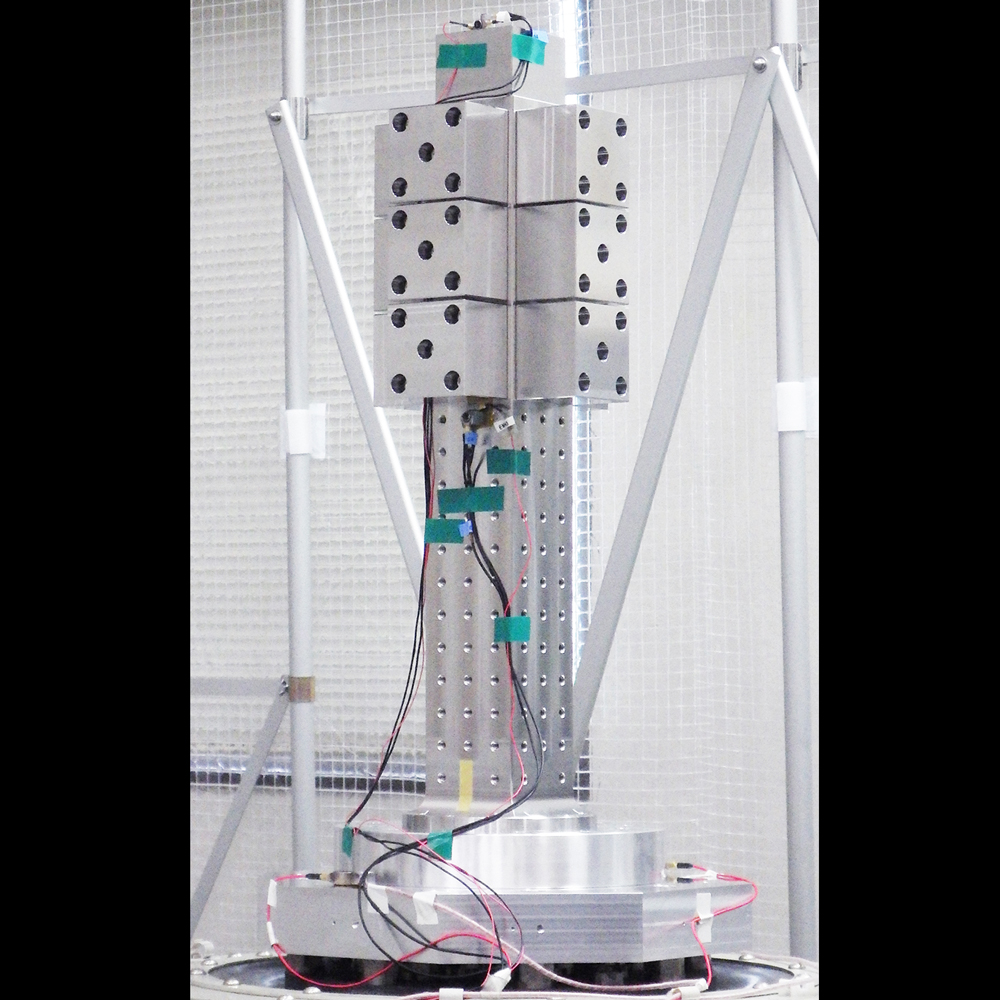

| Assignment | Design / Manufacture / Test Support |